|

Area of application

|

Industrial

|

|

Cutting size paper (mm x mm)

|

2 x 15

|

|

Cutting type paper

|

Cross cut

|

|

Security level ISO/IEC 21964 (DIN 66399)

|

|

|

Shredding material

|

Paper with staples and paper clips, Crumpled paper, CD / DVD / Blu-ray, Plastic card, Floppy disk

|

|

Waste disposal solution

|

Bale press

|

|

Intake width (mm)

|

500

|

|

Inlet / desk height (mm)

|

1.300

|

|

Sheet capacity (80g/m²)

|

80 - 90

|

|

Throughput

|

up to 245 kg/h

|

|

Cutting speed (80g/m²) mm/s

|

100

|

|

Continuous Running

|

yes

|

|

Noise level (idle operation) dB(A)

|

66-68

|

|

Motor protection device with thermal sensor

|

yes

|

|

Power supply (V / Hz)

|

400 / 50

|

|

Other voltages available

|

yes

|

|

Product dimensions W x D x H (cm)

|

109 x 305 x 167

|

|

Product weight (kg)

|

1.424

|

|

Weight shredder (kg)

|

859

|

|

Weight baler (kg)

|

565

|

|

Control operation

|

Touch display

|

|

Visual status indication for ...

|

All activities and issues are shown on display and information e.g. overall operation time, blockages

|

|

Auto reverse

|

yes

|

|

Internal conveyor belt

|

yes

|

|

Hour meter

|

yes

|

|

Overload protection

|

yes

|

|

Safety features

|

Emergency stop bar, Transparent plastic curtain in feeding area

|

|

Lockable master switch

|

yes

|

|

Dust extractor

|

yes

|

|

Castors

|

Baler

|

|

Parking brakes

|

yes

|

|

Material machine housing

|

Metal

|

|

Made in Germany

|

yes

|

|

Certificates / Listings

|

CE, UKCA

|

|

Bale press

|

yes

|

|

Press force of baler (kN)

|

80

|

|

Bale weight (kg)

|

60 - 80

|

1 Only floppy disks / ID cards.

3 Only plastic cards with electronic chip.

Overview

Security requirements for the destruction of sensitive data are constantly increasing worldwide. With increasing security requirements, particle sizes are also becoming smaller and smaller. For many decades, intimus industrial document shredders have proven to be a reliable solution for destroying large volumes of data to high security standards.

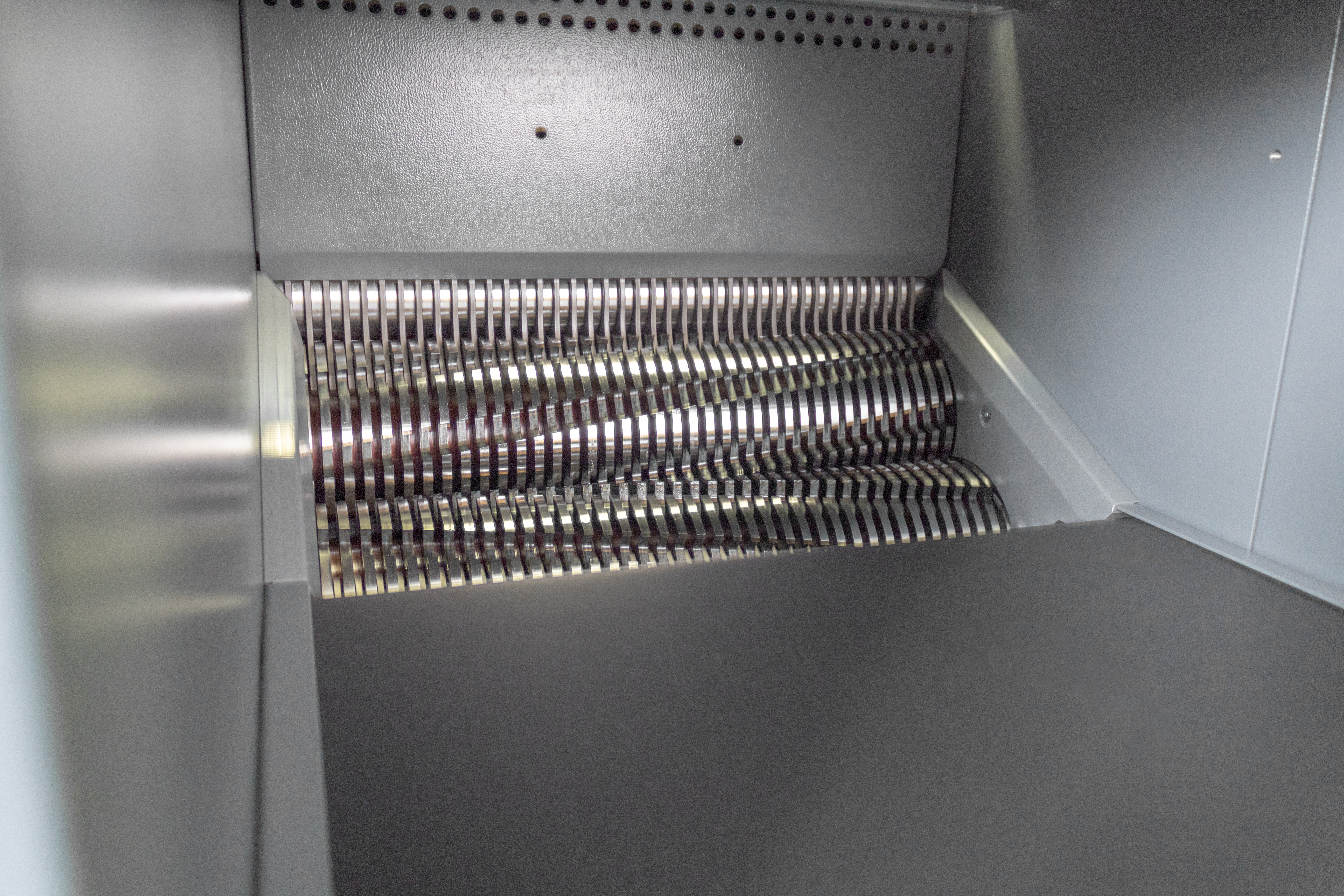

intimus VZ 14.00 is a two-stage system consisting of a pre-shredder and security cutting unit guarantees reliable shredding of personal data. The generous input table with integrated conveyor belt makes it easy to feed in the material. The pre-shredding to 6 x 50 mm particles takes place directly onto a conveyor belt, which transports the shredded material directly to the safety cutting unit of the post-shredder. This cutting unit with a particle size of 2 x 15 mm fulfils security level P-5 in accordance with DIN 66399 (ISO/IEC 21964).

Powered by thermally protected gear motors it handles 80-90 sheets simultaneously, automatically retracting in case of overload. An integrated lubrication system guarantees consistent cutting performance.

The fill level of the pressing chamber is monitored electronically and the pressing process is triggered automatically. Meanwhile, the shredder can continue to be loaded in parallel operation. An optical signal indicates the end of a bale and the cutting process is stopped automatically. Bales can be ejected at the touch of a button.The weight of the bales can be adjusted by a technician as required. By using this system, the volume of shredded material is reduced by approximately 70% compared to loose collection. The material is discharged into clean, low-dust transport containers and packed in weatherproof packagin. The bales are stable in shape.

Key Features

User-friendly operation thanks to a clear panel with safety concept and protective devices.

The hardened cutter shafts made of high-quality tempered steel destroy even stapled materials and ensure a long service life.

Outstanding performance in high-security areas thanks to efficient and continuous feeding of documents by conveyor belt.

A wide emergency stop bar ensures that the machine is switched off immediately in the event of danger.

Automatic control of the pre- and post-shredder. Powerful, thermally protected geared motors with a total drive power of 11,3 kW guarantee smooth, continuous operation.

A maximum of 80-90 sheets can be fed simultaneously.

In the event of an overload, both cutting units reverse automatically and then resume operation.

An integrated automatic oiler ensures consistently high cutting performance and quality.

No Data!

There're no data methods for this query